Your current location:Home > Product > Plasma Welding

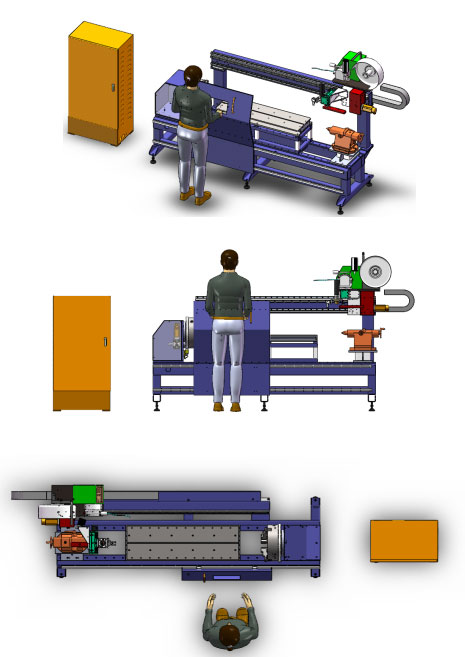

| Model | Effective welding length (mm) | Minimum barrel diameter (mm) | Minimum welding thickness (mm) | Welding speed (mm / min) |

| DZF-300 | 300 | Φ 60 | 0.3 | ≤ 2400 |

| DZF-600 | 600 | Φ 90 | 0.4 | ≤ 2400 |

| DZF-1000 | 1000 | Φ 130 | 0.5 | ≤ 2200 |

| DZF-1500 | 1500 | Φ 160 | 0.5 | ≤ 2000 |

| DZF-2000 | 2000 | Φ 180 | 0.6 | ≤ 2000 |

Now the lose efficiency of mining machinery is mainly caused by friction and wear that results in the huge loss of people's lives and property, the sum is up to hundreds of millions of dollars. Due to the poor working condition and the seve...

Petroleum industry wearing parts: valve, hydraulic rod, valve core, hydraulic cylinder, gate, drill, etc., using Shanghai Duo Mu plasma hardfacing machine can effectively repair petroleum equipment, wear resistance and corrosion resistance, ...

In the process of smelting, the deterioration of machine is due to the natural environment and the external force, such as strike, fatigue and so on. In addition to this those would lead to phenomenon of being defaced of machine, including ...

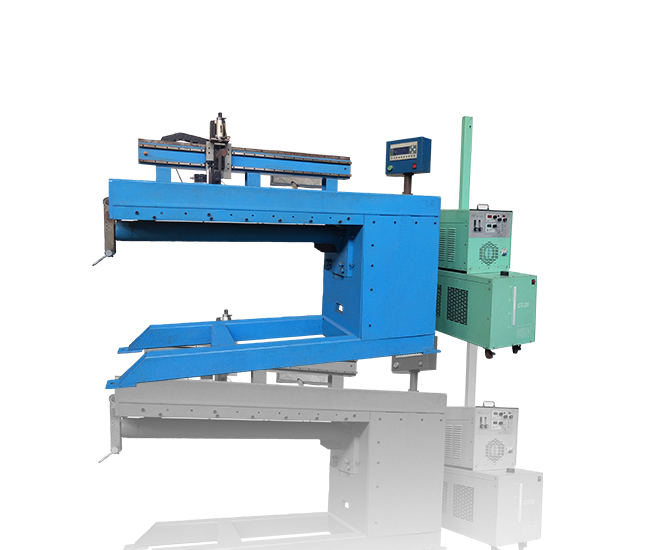

Powder surfacing machine is a metal surface modification equipment independently developed by Duomu Industry, which has completely independent intellectual property rights. The surfacing equipment process is one of the effective technical me...

Powder surfacing machine is a metal surface modification equipment independently developed by Duomu Industrial Company, which has completely independent intellectual property rights. Plasma surfacing technology is mainly used to improve the ...

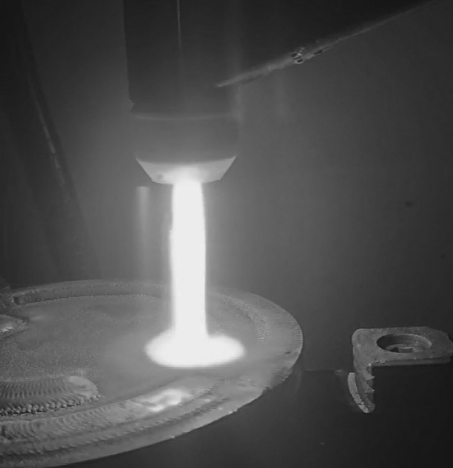

The powder surfacing machine uses a plasma arc high-energy density beam as the welding heat source. The powder surfacing machine has the characteristics of energy concentration, high production efficiency, fast welding speed, small stress an...

The editor of Duomu Industry summarized several protective measures for using powder surfacing machine: Prevent electric shock. The no-load voltage of powder surfacing machine and cutting power supply is relatively high, especially when it i...