According to the editor of Duomu Industry, construction machinery is a general term for various machinery used in construction projects, which are widely used in construction, electric power, water conservancy, highways, mines, ports, municipalities, national defense and other fields. Due to the large size and wide area of construction machinery, the use of powder surfacing welding machine can greatly increase its service life, and can also realize the remanufacturing of parts, which can exert greater economic benefits while saving resources.

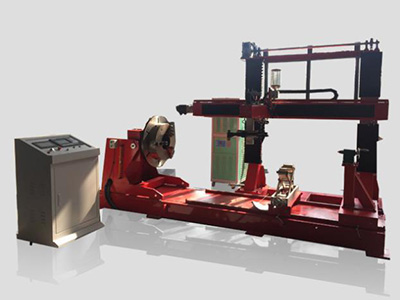

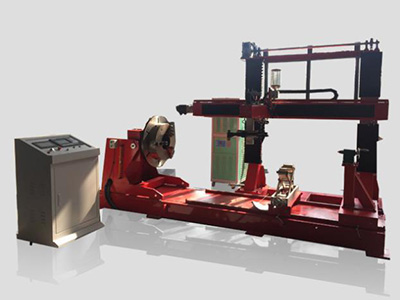

The powder surfacing machine has been used in industry since the 1960s. The tungsten electrode of the welding torch is used as the current negative electrode, the substrate is used as the current positive electrode, and the plasma is used as the heat source. The heat source is transferred to the surface of the workpiece, and the heat source is sent to the thermal energy area of the workpiece. Strengthen hardening. The powder surfacing machine has the advantages of high production efficiency, beautiful appearance, and easy mechanization and automation of the surfacing process, which conforms to the development trend of green manufacturing, and has been more and more widely used in the manufacturing industry.

1. Protective knives.

With the extension and construction of the urban subway track network, the shield tunneling area must not only pass through ordinary soft layers, but also pass through some hard rock sections. The ordinary scraper is suitable for the part of soil and soft rock, and the disc scraper is suitable for hard rock. The single-edged scraper must work on the rock with very high strength (above 200MPa). In order to increase the service life of the hob, the common powder surfacing machine is used to surfacing hard alloy materials on the surface of the hob ring, which can greatly improve the wear resistance and compression resistance of the workpiece, extend the time of tool replacement, and improve the excavation efficiency of the workpiece .

2. Rotary excavator picks.

The rotary excavator does not squeeze the soil when forming a hole, has low vibration, low noise, low pollution, high degree of automation, fast excavation speed, safety and environmental protection, and high efficiency. It can be widely used in industrial and civil construction. The pressure of the pressurizing system of the rotary excavator is transmitted through the drill pipe, so that the bucket picks cut into the rock and soil. Plasma arc surfacing welding wear-resistant alloy materials can effectively improve the surface strength of the wear-resistant belt at the tip of the pick, and it is a very effective surface strengthening process.

Three, plunger

The plunger is an important component of the plunger valve and is widely used in construction machinery. The cooperation of the piston and the cylindrical sleeve belongs to the general cooperation of power transmission, which drives the connecting rod to complete the movement. The editor of Duomu Industry recommends that a layer of wear-resistant alloy material be deposited on the surface of the plunger with a powder surfacing machine, which can effectively improve its wear resistance and is an important guarantee for the long-term stable operation of construction machinery.