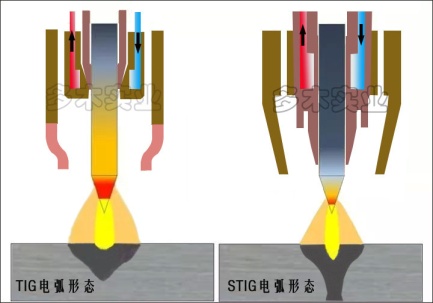

【Principle of Welding】

The high penetration keyhole STIG welding system (SWS-1000) is a brand new arc welding system. It achieves the effect of plasma arc through high-efficiency electromagnetic compression of the arc. The arc energy is concentrated during welding, and the arc pressure and molten pool liquid state during welding. The surface tension of the metal is balanced to form a stable pinhole effect, and it has super penetration ability. It can penetrate steel plates of less than 12mm at one time. It is a kind of between argon arc welding (TIG) and plasma (plasma) The new welding process.

【System composition】

Welding main power supply (built-in arc voltage tracking), cooling water tank, STIG welding gun, precision wire feeder (optional)

The system adopts an all-in-one structure, and the welding main power supply, cooling water tank, arc voltage tracking, and control system are integrated.

【STIG welding characteristics】

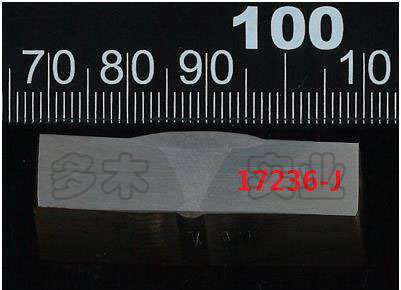

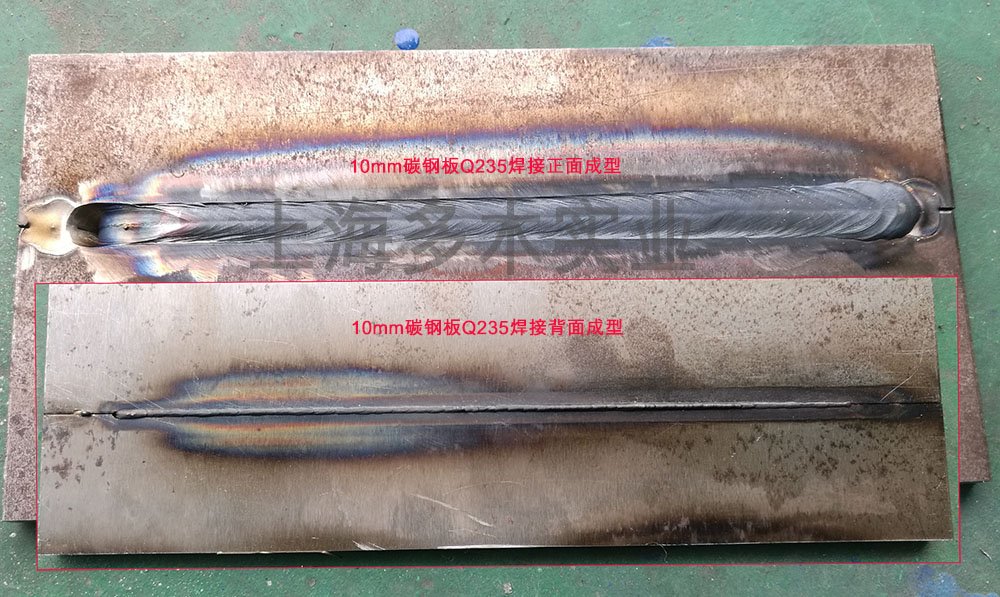

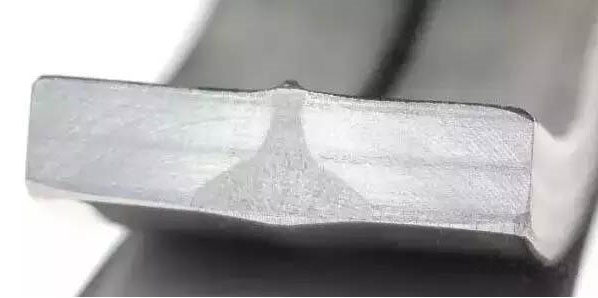

STIG arc welding technology is a high-speed full penetration weld welding technology. It can penetrate metal materials (such as titanium alloy) less than 16mm at one time without grooves. The weld is formed perfectly, and the weld is welded on both sides. The forming and welding speed is 5-10 times that of ordinary argon tungsten arc welding technology. The width of the back welding seam is 2-3 mm, and the front welding seam width is usually about 1.5 times the thickness of the board. The welding seam is 100% of the parent material layer without multiple fusion lines, which completely eliminates slag inclusion, pores and common welding seams. defect. The non-corrugated welding pool of high-efficiency deep penetration arc welding ensures the super high quality of the cover layer, completely eliminating the need for back root cleaning, surface polishing, cleaning and grinding.

【SWS-1000 System Features】

The SWS-1000 high penetration STIG welding system adopts an integrated design, and the welding power supply system, cooling system, and arc voltage tracking system are integrated. The equipment is simple, the optimized failure rate is low, and the operation is flexible and convenient.

The SWS-1000 type high penetration STIG welding system has its own arc voltage tracking system, which can automatically track the changes in the height of the weld, ensure a constant distance between the tungsten electrode and the weld, increase the adaptability to the weld gap, and achieve the consistency of the weld And high quality,

At the same time, the system has a communication function, which can realize seamless connection with peripheral automation equipment and realize remote control of welding parameters (welding current change: current rise and fall, gas protection time setting: early air supply, delayed air stop, etc.). Meet the needs of dynamic welding in the welding process and realize fully automated welding.

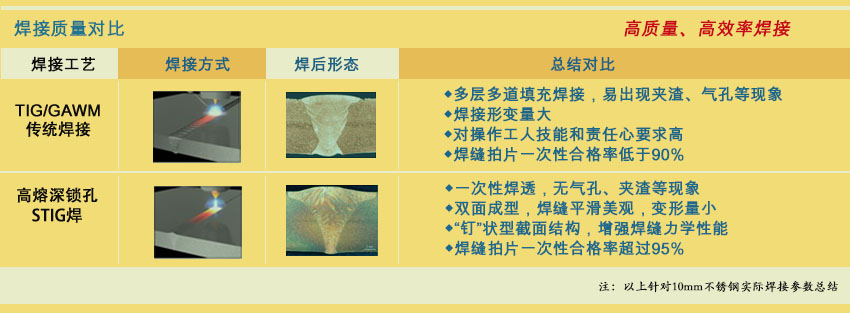

【SWS-1000 system welding advantage】

1. High speed, high quality and high efficiency

SWS-1000 type high penetration STIG welding system adopts high-efficiency electromagnetic compression arc, high arc energy density, stable small hole effect formed in the welding process, strong penetrating ability, can penetrate 10mm steel plate at one time, single-sided welding and double-sided forming , The welding seam is beautiful, the welding efficiency is high, the welding quality is good, there is no pores, slag inclusion, etc., the one-time pass rate of the film is more than 95%, and the welding speed is fast. Taking 10mm stainless steel as an example, the welding speed can reach 300mm/min, which is ordinary TIG welding. It is more than 8 times higher than the traditional GMAW/TIG welding process, which has obvious advantages.

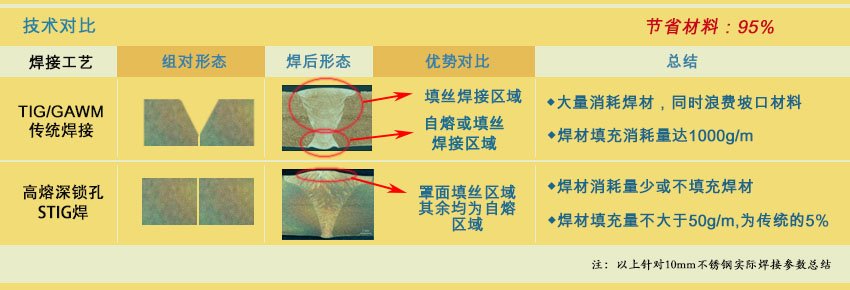

The following is a data comparison table summarizing the actual welding parameters of 10mm stainless steel:

2. Save manpower and material resources and save costs

The SWS-1000 type high penetration STIG welding system has the characteristics of high-efficiency welding without grooves under a certain thickness, eliminating the need for repeated fill welding of grooves and groove welds, which can save a certain amount of equipment, manpower, and consumables; The high-quality welding with high permeability and full penetration reduces the phenomenon of pores and slag inclusions, avoids other conventional welding pores, slag inclusions and other phenomena in the later grinding and repair welding process, which saves a lot of manpower; single-sided welding and double-sided forming, The welding seam on the back is narrow, and the width of the welding seam is about 2-3mm, which eliminates the cumbersome cleaning of the back and saves a lot of manpower and material resources. At the same time, it is used in the welding of ordinary low-carbon steel medium and thick plates and the deep groove bottoming process of thick plates. Its quality, efficiency and cost advantages are unmatched by other current technologies, and it has more competitive advantages than traditional submerged arc welding and GMAW.

【Application field】

1. Petrochemical industry.

2. Food and pharmaceutical industries.

3. Aerospace.

4. Electric power industry, power plants (including nuclear power industry).

5. Water treatment industry.

6. Shipbuilding.

7. Boilers and pressure vessels (mainly include: direct welding and girth welding in the manufacturing process of normal and high pressure piping and vessels such as pipelines, heat exchangers, pressure vessels, storage tanks, reactors, etc.)。

8. Prefabrication of pipelines and assembly of plates in large-scale infrastructure construction

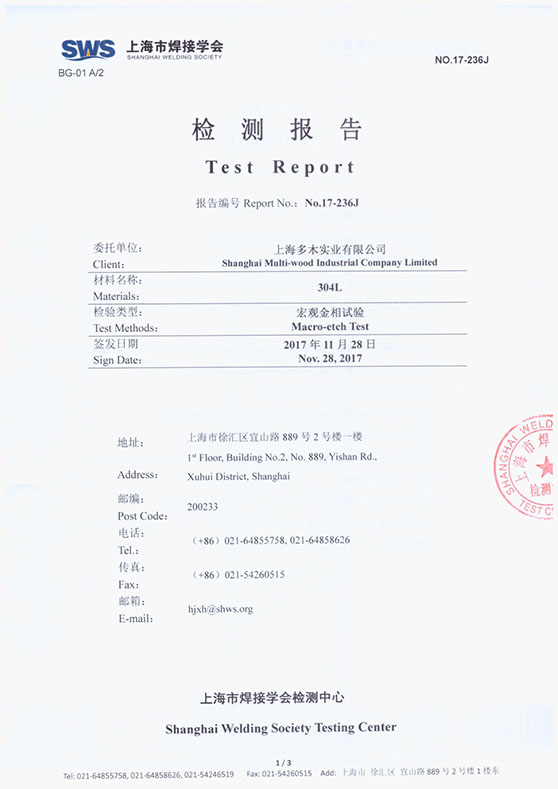

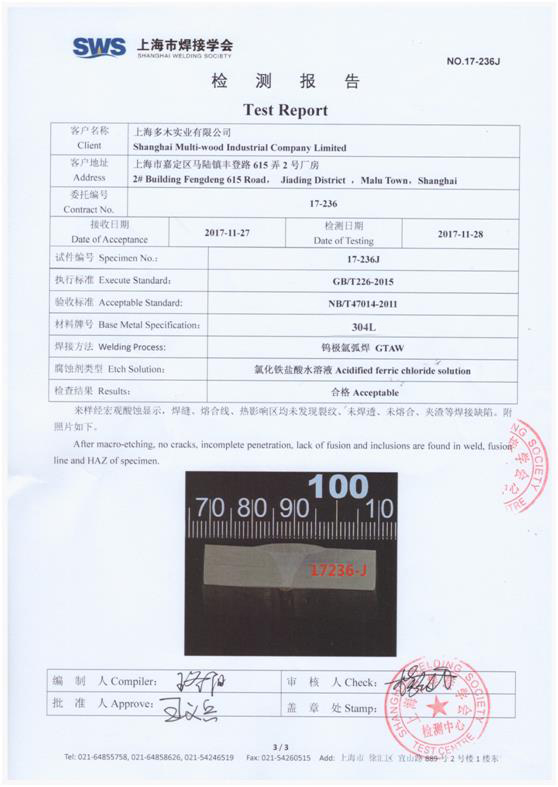

【Welding experiment report】

Shanghai Duomu Industrial Co., Ltd. is a high-tech industry specializing in power supply development. Welding power supply is my key project. The series of welders developed have reached or exceeded the international advanced level, and are well recognized by customers and have a wide customer base. And popularity. The products are professionally used for welding of precision parts and thin plates, surfacing welding of valves, rolls, picks, etc., welding repair of molds, mechanical shafts, etc., and have been widely used in electronic appliances, coal mining machinery, aerospace and many other fields.