Shanghai duomu Industry Co., Ltd. is a high-tech industry specializing in the development of power supply, in which welding power supply is my priority Point project, the development of a series of welding machine has reached or exceeded the international advanced level, deeply recognized by customers, with a wide range of customer groups and visibility. The products are mainly used in welding of precision parts, thin plates, etc., surfacing welding of valves, rolls, pick, etc., and welding repair of moulds and mechanical shafts, etc. it has been widely used in many fields such as electronic appliances, coal mining machinery, aerospace, etc.

How to design the surfacing scheme for the middle groove of scraper conveyor?

1. Large cross intermittent weld bead

In addition to improving the wear resistance of the plate in the middle groove, it is also necessary to ensure that the wear of itself and the scraper is uniform in the process of use. Therefore, the position and shape of the wear-resistant weld bead are very important. Through the overlaying of various patterns such as rectangle, diamond, strip on both sides and splayed on both sides on the medium plate, a large number of tests and analysis show that the best effect is the large cross intermittent weld bead.

2. Design and advantages of large cross intermittent weld bead

(1) The wear-resistant weld bead is evenly distributed, and the distance between adjacent welding passes in the same direction is 450-500mm. Each welding pass adopts intermittent welding, and the weld length is about 100 mm, and the spacing is about 100 mm.

(2) Using large cross intermittent welding bead, the middle plate, scraper and chain of the middle groove can be worn evenly in the process of use, and the pulverized coal can be retained between the welding passes, which can also play the role of setting off and reducing wear.

(3) After the weld bead is broken, it is beneficial to reduce the welding stress and welding deformation

(4) After welding, there is no need to correct the process, which makes the manufacturing process simple and easy.

Product Application

Middle groove

Machine name:

Product Description:

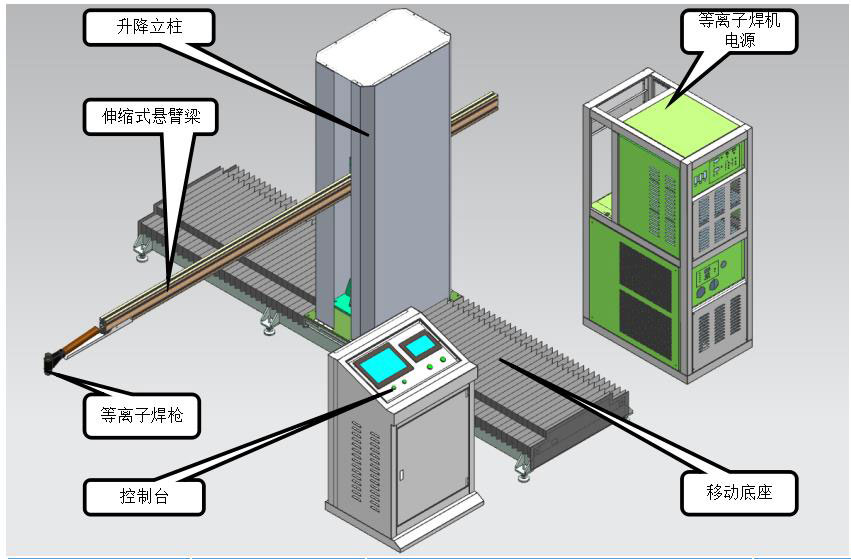

Features of CNC surfacing machine tools: