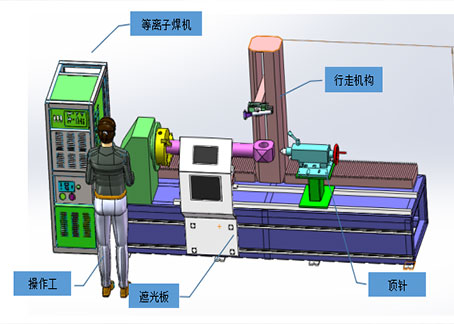

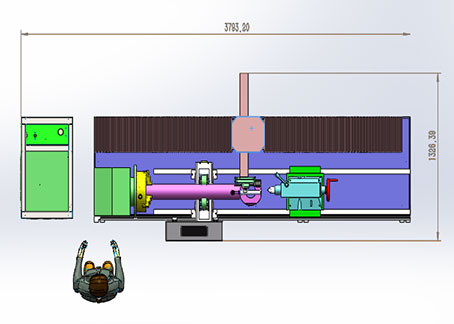

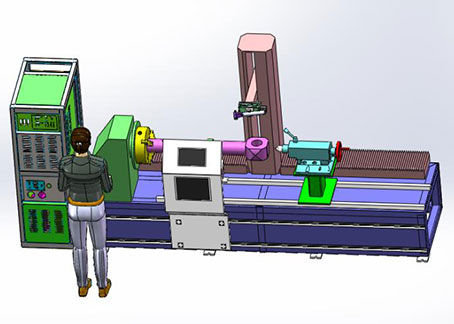

| Serial number | name | model | number | remarks |

| one | Plasma welding machine | DML-V03BD | one | |

| two | Plasma welding torch | DPT300 | one | |

| three | Rifles with inner holes | DNPT300 | one | It can be extended to 900mm |

| four | Circulating cooling water tank | DML-V03BD | one | |

| five | Cross manipulator | H2000V | one | |

| six | Wiggler | DM-80 | one | Maximum swing 50 |

| seven | Rotating head | Nonstandard | one | |

| eight | Chuck | K11-500 | one | |

| nine | Control system | plc | one | |

| ten | Electrical control cabinet | Nonstandard | one | |

| eleven | Adjustable height roller bracket | HG-6 | ||

| twelve | Thimble | customized | one | |

| thirteen | electric machinery | 0.75kw | one | Xinjie |

| 86 stepper motor | two | Wheatstone | ||

| 57 stepper motor | one | |||

| fourteen | touch screen | Viatron | one | |

| fifteen | External fence | Non standard self made | one |

|