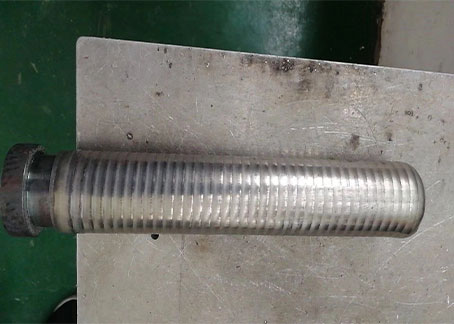

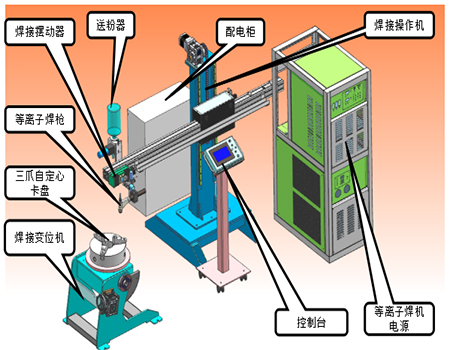

It is suitable for surfacing and repairing the damaged surface of the outer circle, inner hole and end face of general shaft parts and pipe parts. It can also be used for surfacing and repair of disk parts.

|

Configuration items |

Model and brand |

Description of main parameters |

|

Arc voltage tracking |

Multi wood integration |

|

|

Current communication |

485 communication |

|

|

touch screen |

Wellington |

7-inch screen tk6071iq |

|

Control system |

Mitsubishi, Japan |

FX series PLC |

|

Console |

Multiwood manufacturing |

Mobile control platform, handheld touch control box |

|

Electrical components |

chint |

|

|

Transverse mechanism |

Research and control stepping motor |

Effective stroke 1200mm |

|

Lifting mechanism |

Research and control stepping motor |

Effective stroke 1000 mm |

|

Spindle motor |

Xinjie servo motor |

The rotation speed is 0.01r/min ~ 2.5r/min |

|

Welding positioner |

HBT-06 |

Rated load 600kg |

|

Welding wiggler |

BDQ-80 |

Swing speed 1-30 mm / S The swing distance is 3-60 mm |

|

Three jaw chuck |

K11-500C |

The clamping range is 25-500 mm |

|

Reference footprint |

Length 3400 mm, width 1800 mm, height 2100 mm. |

|