Resistant to heat and crack

Usually for the rough roll strength, thermal crack resistance as the main requirements;The working roll weight of a small 20-h mill is only about 100 grams, while the backing roll weight of a broad plate mill is over 200 tons.When selecting the roll, the main material (cast iron, cast steel or forged steel of various grades) should be selected according to the basic strength requirements of the rolling mill for the roll.

Hardness

And the high speed of the finishing roll, the final product of the rolling must have a certain surface quality, hardness, wear resistance, etc., as the main requirements.Then consider the wear resistance of the roll when it is used.Because the wear mechanism of roll is very complex, including mechanical stress, heat action during rolling, cooling action, chemical action of lubricating medium and other actions, there is no uniform index to comprehensively evaluate the wear resistance of roll.Because the hardness is easy to measure and can reflect the wear resistance under certain conditions, the radial hardness curve is generally used to approximate the wear resistance index of the roll.

Impact resistant

In addition, there are some special requirements for the roll, such as when the amount of pressure is large, the roll is required to have a strong biting ability, more impact resistance

Degree of finish

When rolling thin specification products, the rigidity of the roll, the uniformity of microstructure and performance, processing accuracy and surface finish requirements are more strict;

machinability

When rolling the section steel with complex section, the machinability of the working layer of the roll body should be considered.

When selecting rollers, some of the performance requirements of rollers are often opposite to each other, and the purchase and maintenance costs of rollers are very expensive, so the pros and cons of technology and economy should be fully weighed to decide whether to use cast or forged, alloy or non-alloy, single material or composite material.

Product Application

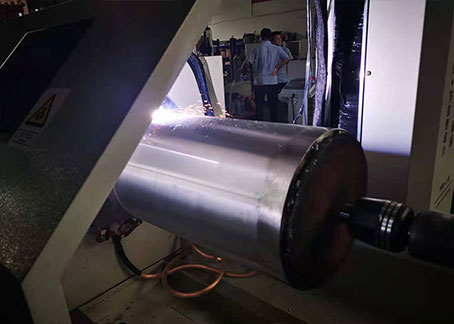

Roll

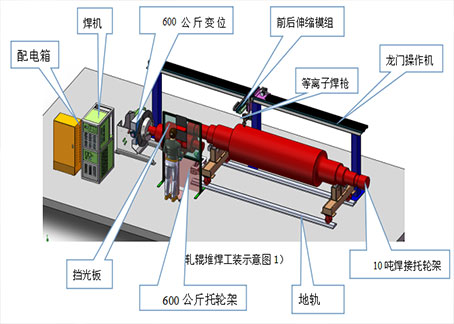

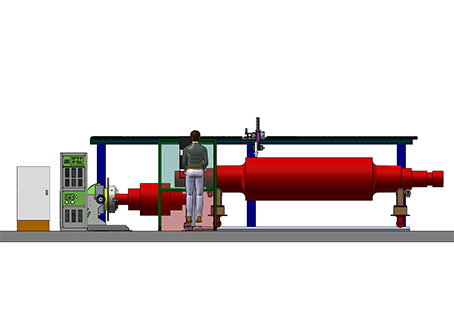

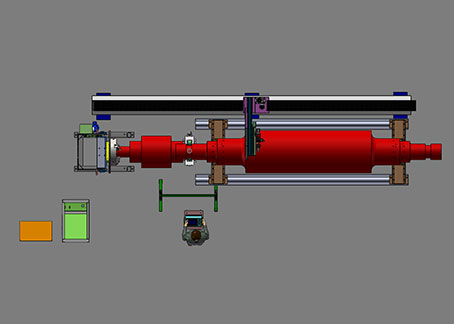

Machine name:

Product Description:

Features of CNC surfacing machine tools:

Product Description

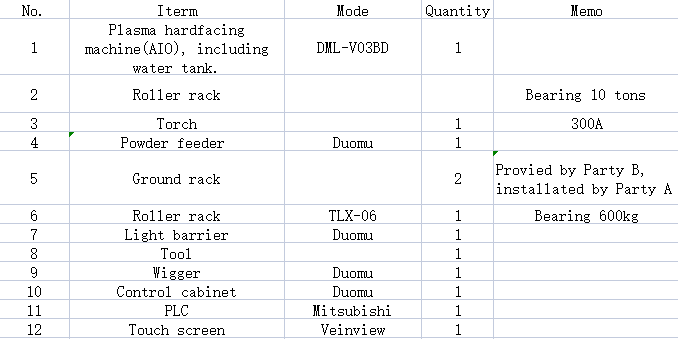

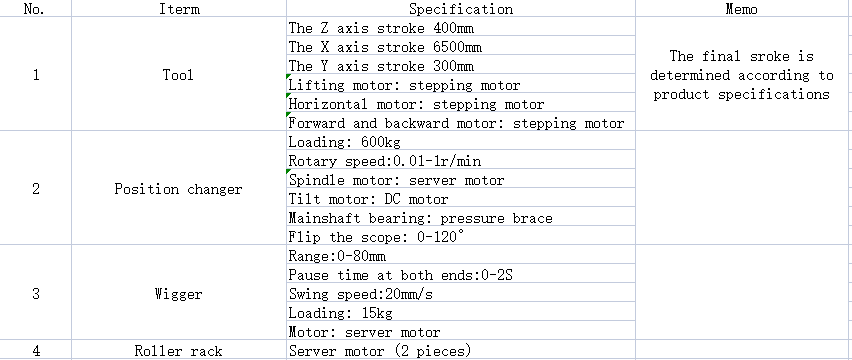

parameters and performance