Petroleum industry wearing parts: valve, hydraulic rod, valve core, hydraulic cylinder, gate, drill, etc., using Shanghai Duo Mu plasma hardfacing machine can effectively repair petroleum equipment, wear resistance and corrosion resistance, prolong the service life of machinery.

1 Classify

(1) Corrosion wear.The phenomenon of material loss caused by chemical reaction or electrochemical reaction between friction surface and surrounding medium is called corrosive wear.Generally, it is a slow process that starts from the surface and gradually develops into the interior of the metal, accelerating wear under high temperature and strong corrosive media.The cylinder piston group is often subjected to corrosive wear, the reason is that the condensed water on the surface of the cylinder wall directly eroses the surface of the cylinder wall, and the acidic water will make the wear more serious.Engine parts working at high temperature, such as valves, cylinder liner, etc., because the fuel in the combustion process of CO2, SO2, N2, they and hydration to generate a variety of acids, corrosion parts.

(2) Abrasive wear.Abrasive wear is caused by the relative motion of external hard particles or micro-peaks of the hard surface on the dual surface of the friction pair, which is called abrasive wear.The engine needs to breathe in air when burning, and it is difficult to absolutely avoid dust inhalation into the engine with the air even if the air filter is good.Due to the inhalation of dust caused by the strong wear, especially at the place in China where is drought, less rain, wind and sand areas, the performance of this coercive wear is more distinct.

(3) Adhesive wear.When the friction pair is in relative motion, due to the roughness of the friction surface, the surface contact is only at some points. Under the action of external load, the average unit pressure of the contact point is very high, and the elastic or plastic deformation occurs at the contact point, leading to the destruction of the metal surface film, and the metal on the two friction surfaces directly contact.Adhesive wear refers to the local metal adhesion on the contact surface of the friction pair during sliding friction, which is destroyed at the adhesion point in the subsequent relative sliding, and a form of wear in which the metal shavings are pulled down from the surface of the part or the surface of the part is scraped.For example, when reliable lubrication can not be obtained between the cylinder liner and the piston ring, local dry friction will occur, resulting in direct metal contact between the cylinder liner and the piston ring, forming metal fusion, softening, so that the relatively soft cylinder liner surface damage.

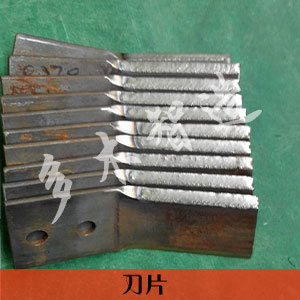

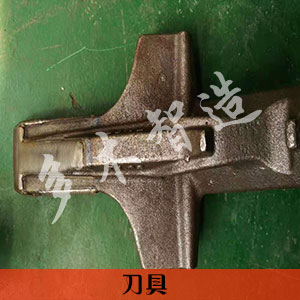

Agricultural machinery easy to wear parts: returning tools, rotary tillage tools, grinding tools, etc., using Shanghai Duo plasma surfacing machine can effectively repair agricultural machinery, resistance of wear and corrosion, prolong the service life of machinery.